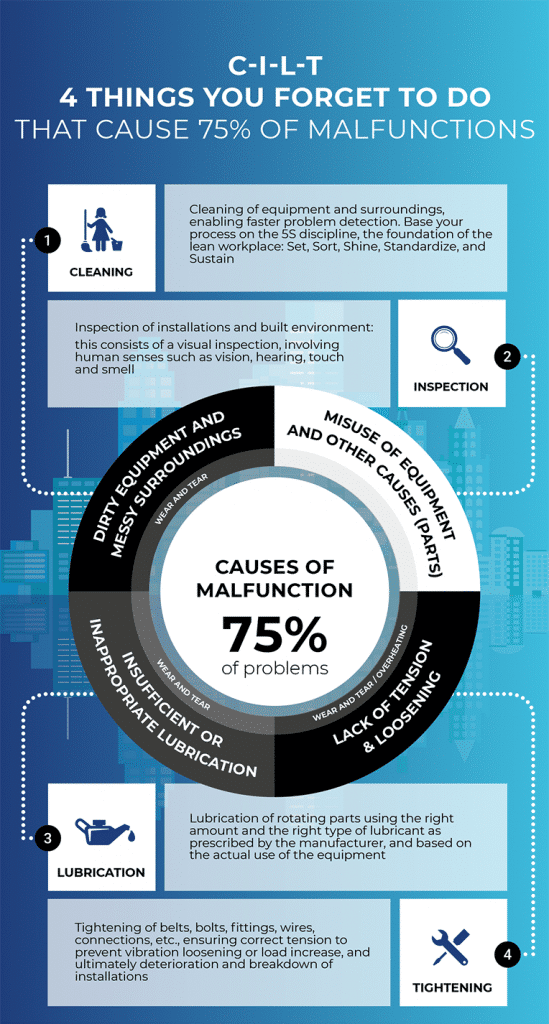

CILT: 4 principles of basic preventive maintenance (infographic)

Equipment failure can often be traced back to a few basic causes. What are they, and how to dramatically improve the reliability and uptime of your facilities and installations?

Download Your Infographic:

Basic property maintenance

Our infographic explains the key principles of CILT in basic preventive maintenance. “Cleaning is inspection” and other lessons from industrial maintenance for the built environment.

CILT: critical in any maintenance concept

These are the 4 things you should always be doing, whether you choose a reactive, run-to-fail maintenance concept for non-critical assets or apply preventive or predictive maintenance to optimize uptime and performance.

- Cleaning of equipment and surroundings, enabling faster problem detection. Base your process on the 5-S system, the foundation of the lean workplace: Set, Sort, Shine, Standardize, and Sustain

- Inspection of installations and built environment: this may be a visual inspection (involving human senses such as vision, hearing, touch, and smell) or involve sensing technology that can detect anomalies and failure patterns remotely

- Lubrication of rotating parts using the right amount and type of lubricant as prescribed by the manufacturer

- Tightening of belts, bolts, fittings, wires, connections, etc., ensuring correct tension to prevent vibrations or load increase, and deterioration and breakdown of installations